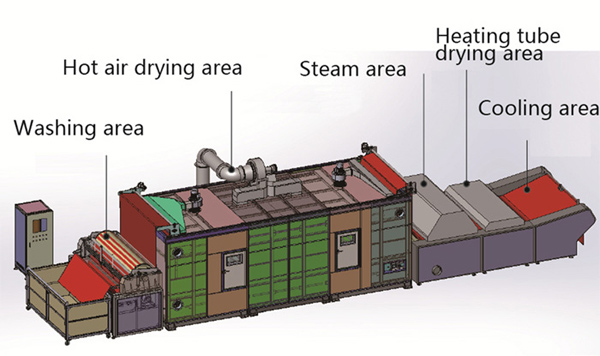

| FABRIC WASHING AND SHRINKING MACHINEJY-WS-12MMachine Concept: Let the fabric pre-shrink effect reach 100%, save energy and reduce emissions, provide environmentally friendly textile finshing solutions. |

MACHINE STRUCTURE INTRODUCTIONFabric washing and shrinking machine includes water washing area, hot air drying area, steam area, heating tube drying area and cooling are. • The washing area includes a scrubbing section and a water spraying section. • The scrubbing section is provided with a scrubbing water tank and a fabric guide roller group. • The scrubbing water tank is divided into a desizing area and an ultrasonic cleaning area. • The ultrasonic cleaning area is provided ith an ultrasonic cleaning device, there are a water tank and a shower head assembly. The shower head assembly is used to finse the fabric, the water is used to store the wter dropped by washing the fabric, and the water tank connects with the scrubbing water tank. |  |

ADVANTAGES

• Fully soften the fabric, improve the shrinkage effect, the feeling of fabric & quality of fabric.

Squeeze the fabric guide roller and flatten the fabric guide roller to squeeze the cloth first and then flatten to simulate the traditional rubbing water washing.

• Let the fabric pre-shrink effect reach 100%.

After a series of processes such as desizing, rubbing, ultrasonic cleaning, and water spraying, the fabric is thoroughly washed and then dried.

• Reduce time and labor costs.

After using this machine, the fabric can be used directly in next step, which greatly simplities the fabric finishing processing process.

• Realized energy saving and emission reduction, green textile manufacturing concept.

When the fabric is washed in the scrubbing water tank, some water will be taken away due to the water absorption of the fabric, the water of the sprinkler assembly will fall into the water tank in the meantime, and the water will be continuously replenished into the scrubbing water tank, thereby forming a water cycle and no direct discharge of wastewater.

SPECIFICATION

| Front section- Washing area & Hot air drying area | |

| Washing area length | 1170mm |

| Hot air drying area dimension(L*W*H) | 6000×2445×2210mm |

| Height of cloth hanging in hot air drying area | 1319mm |

| Total hanging length of cloth | 88m |

| Input fabric motor power | 120W |

| Output fabric motor power | 120W |

| Blower motor power | 800W×2 |

| Hot air motor power | 2.2kw |

| Cyclic Geared Motor Power | 1.1kw |

| Steam ironing cylinder drive motor power | 400W |

| LED light power | 50W×2 |

| Steam ironing canister steam pressure | ≤0.36Mpa |

| Steam ironing canister steam consumption | 16kg/h |

| Pressure of steam ironing canister pressing cylinder | ≤0.5Mpa |

| Steam ironing canister temperature | 120-130 °C(Steam heating) |

| Hot air drying tempreature | Adjust according to different fabric demand |

| Hot air drying heat source | Electric, Natural gas, diesel,etc |

| Back section- Steam area & Heating tube drying area & Coo|ing area | |

| Steam consumption | 100kg/h |

| Steam pressure | 0.4-0.7 Mpa |

| Heating tube drying temperature | Adjustable ,≤200 °C |

| Exhaust motor power | 0.8kw |

| Sway fabric motor power | 0.37kw |

| Conveyor motor power | 0.37kw |

| Vibration motor power | 0.09kw |

| Suction motor power | 0.8kw |

| Electric heating power | 6kw |

| Technical specification | |

| Max. rolled fabric diameter | 40cm |

| Max. fabric width | 2100mm |

| Working speed | 0-15m/min |

| Total power | 14kw |

| Voltage | AC 380V 50HZ |

| Overall dimension | 12470×2610×2210mm |

English

English 中文

中文